描述

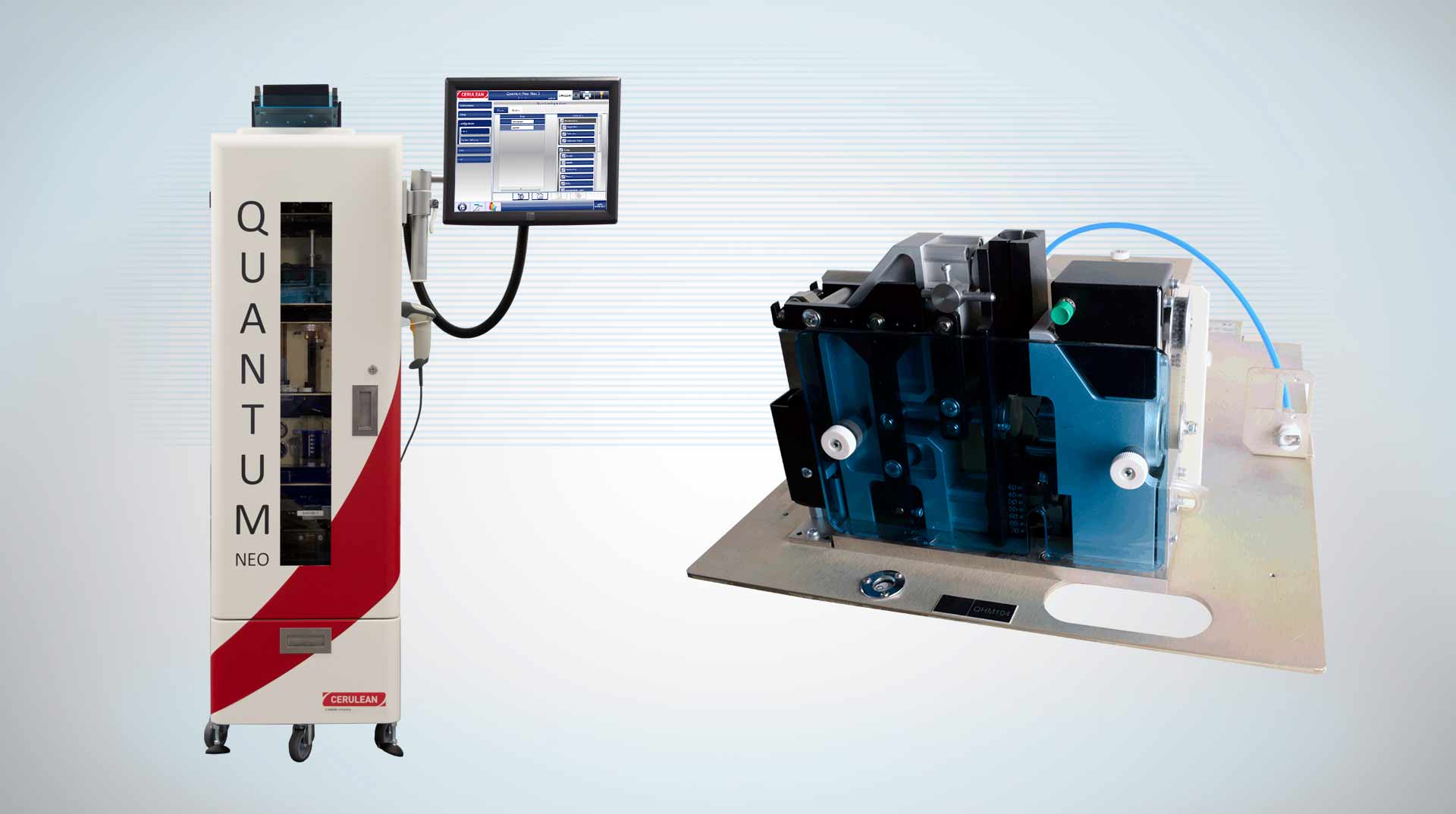

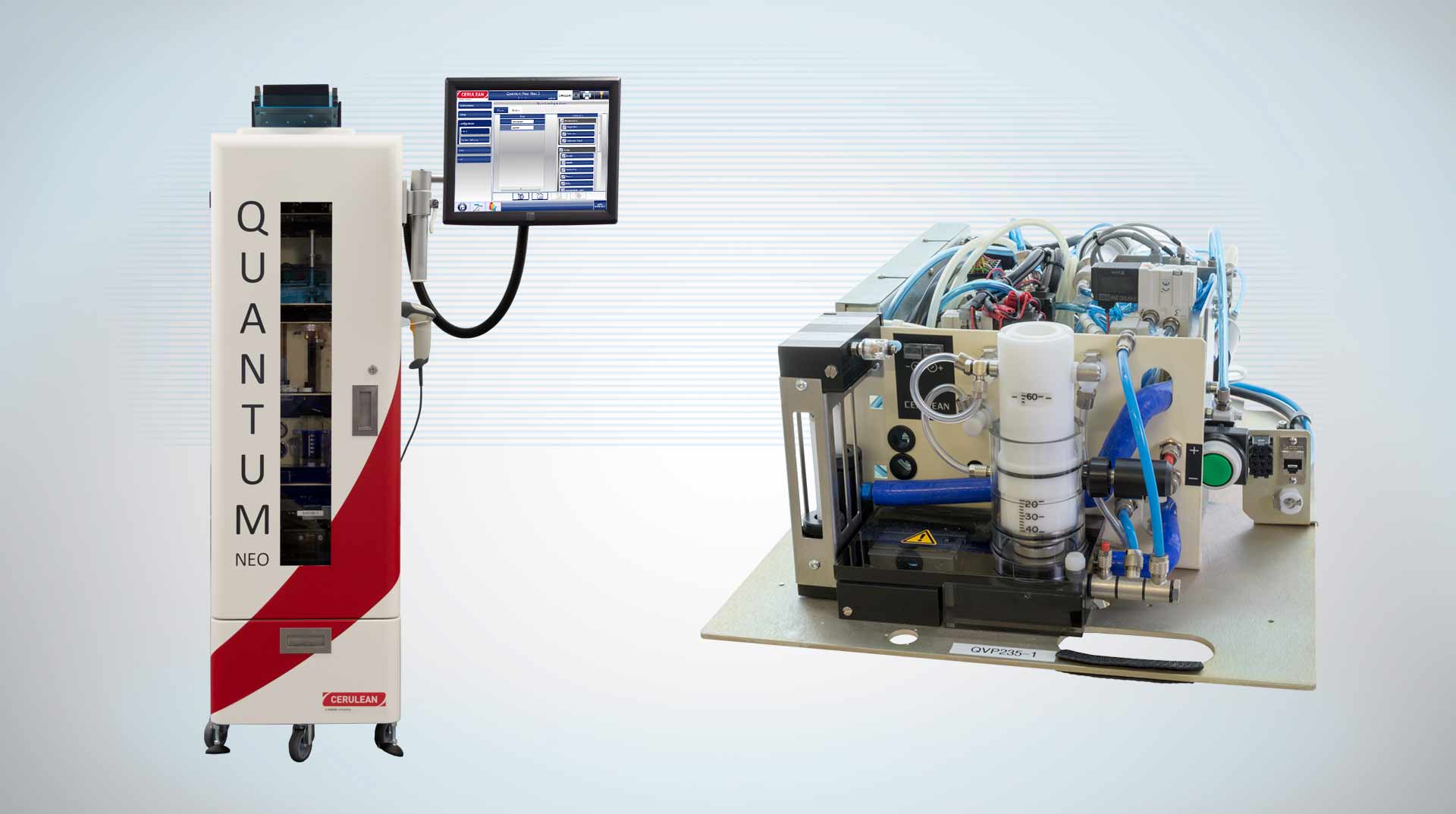

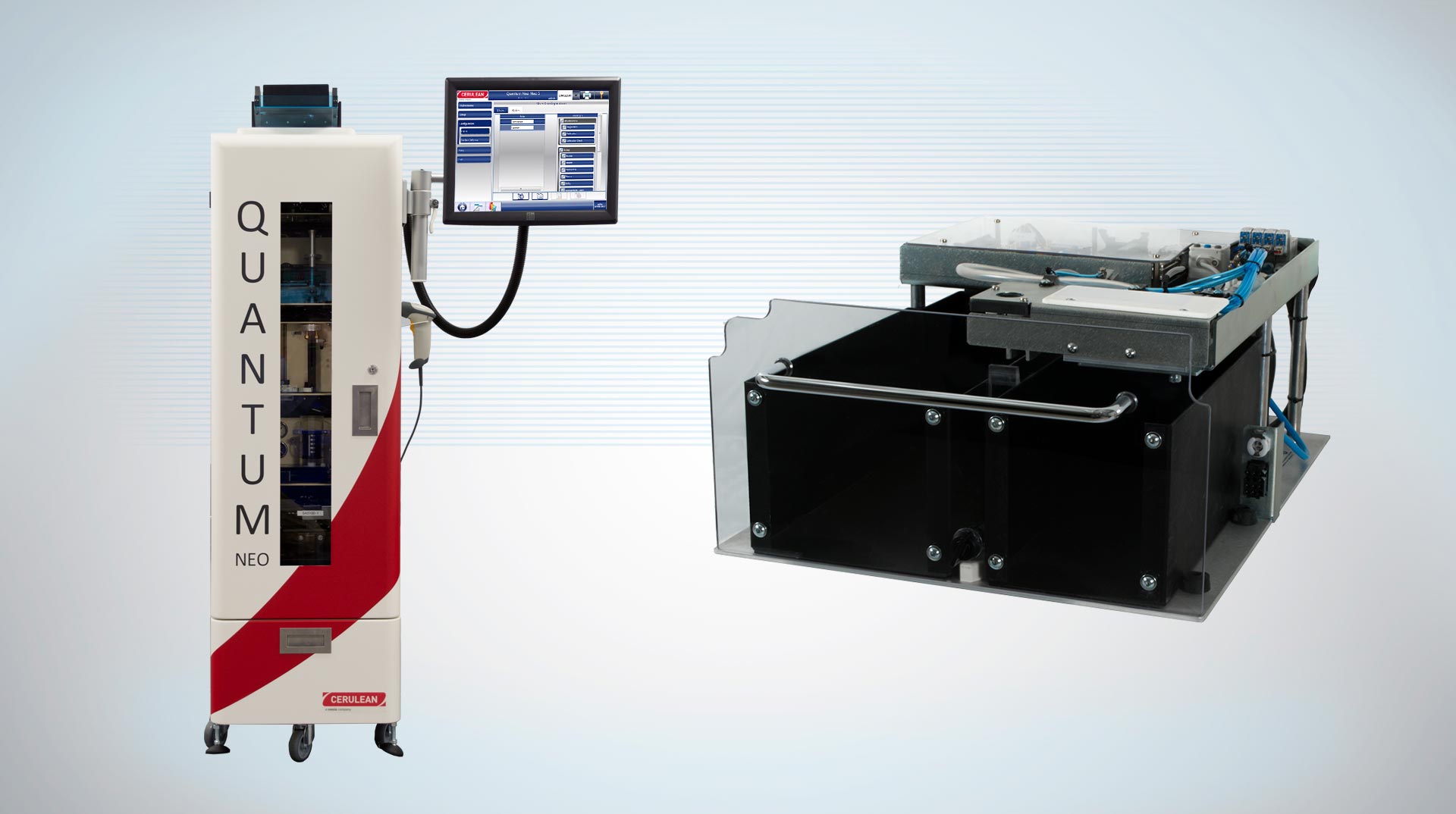

The basic Quantum Neo system provides a frame to which up to five measurement modules can be added as required. It takes seconds to configure and is equipped with a user interface that provides key information, a graphical representation of process capability and stores the data in a network-accessible ODBC Compliant database.

There are more than 20 module measurements available- please see individual datasheets for further information about Quantum Neo shelves.

-

A: Ventilation and Pressure Drop (Auto-calibration Pressure Drop) - Cigarette

- B: Pressure Drop - Filter (vacuum)

- C: Diameter Size - Laser

- D: Pressure Drop (Auto-calibration Pressure drop) - Filter (vacuum)

- E: Pressure Drop - Filter (pressure)

- F: Auto Sorter - Fixed (at the bottom of the machine in place of the waste bin)

- G: Non-contact length

- H: Hardness

- J:

Ventilation and Pressure Drop (Auto-calibration Pressure Drop and Ventilation) - Cigarette

- K: Moisture and Density - Cigarette

- M: Moisture - Filter

- N: Non-contact length

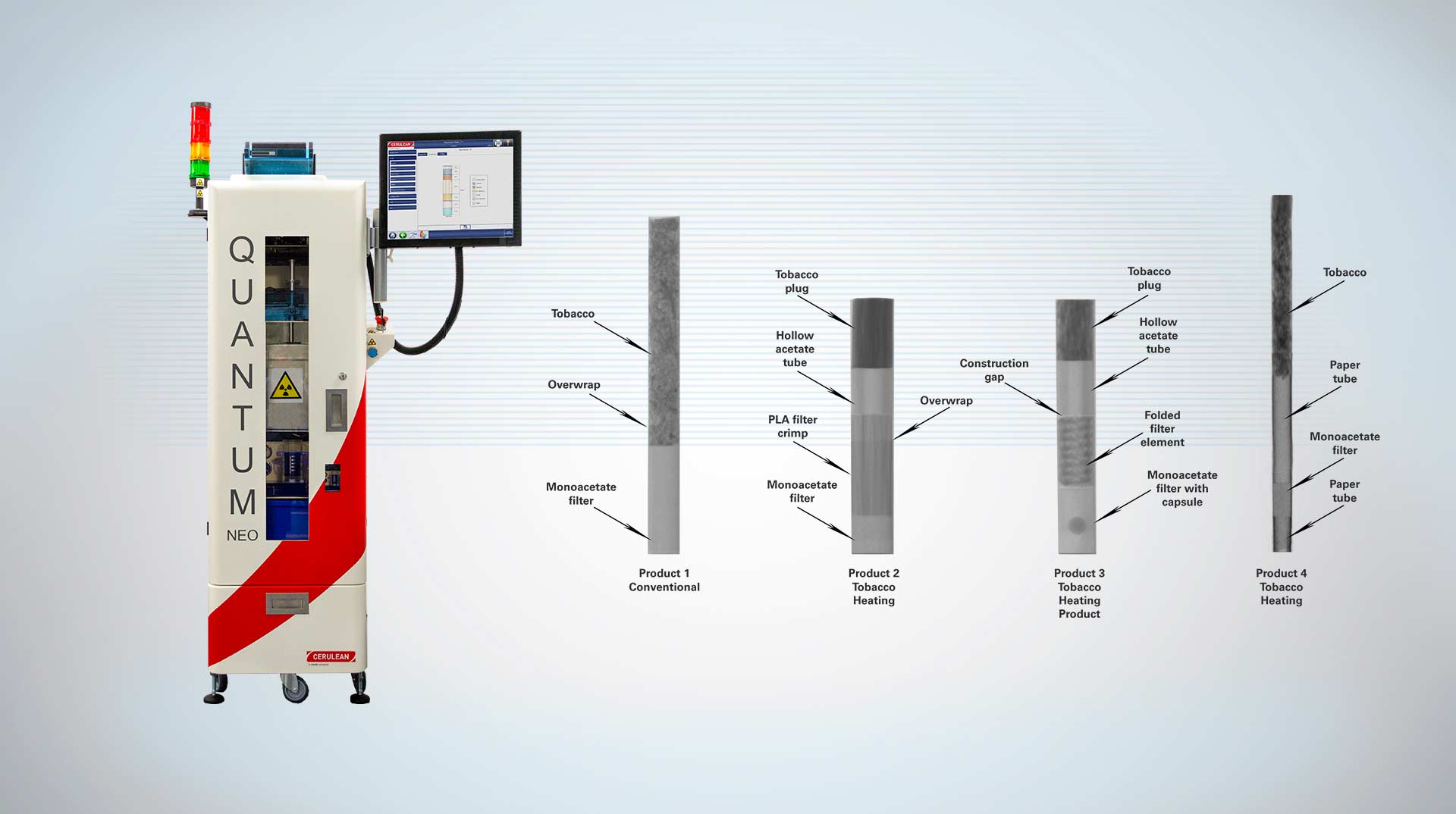

- Q: X-ray

- R: Auto Sorter - Shelf (replaces a measurement shelf)

- S+: Multi-position diameter Size - Laser

- U: Moisture, Density and Length

- V:

Ventilation and Pressure Drop - Cigarette

- X: Individual weight (Auto-calibration)

- Y: End-form analyser

- Z: Diameter Size - Laser (extended positional range)

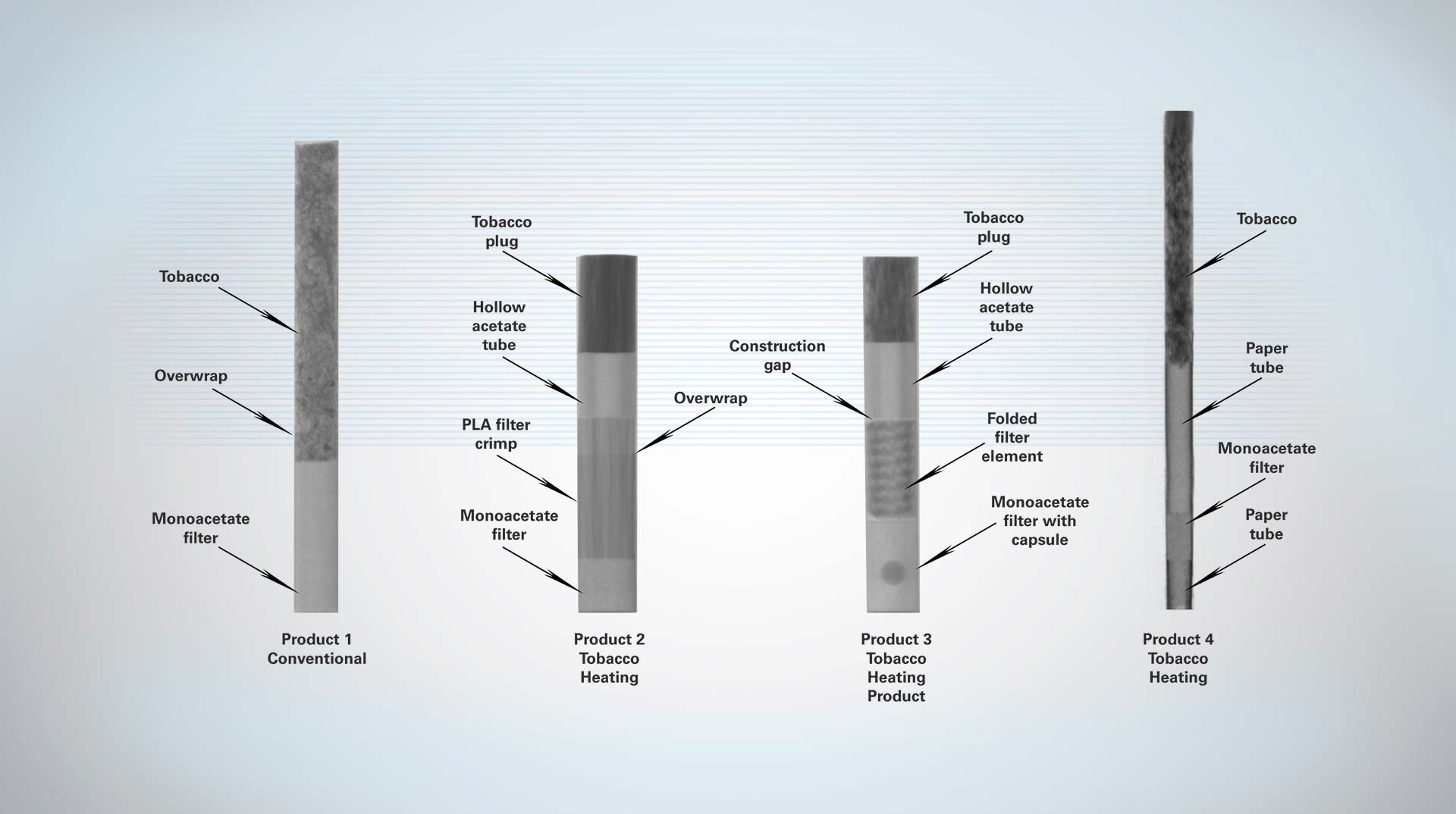

The Quantum Neo X-ray imaging shelf allows visualisation and accurate measurement of the size and position of hidden elements without damaging or destroying the product under test. Now as part of the Cerulean Quantum Neo test station system, it is a flexible and comprehensive platform for Quality Control testing of filters and cigarettes.